Precision Mold Maintenance Specialist —Electric mold cleaning machine

● Improve cleaning efficiency by more than 5 times

●Reducing the non-performing rate due to product size changes

●Bite surface transfer rate UP

●Deep into the mold to remove dirt such as oil, rust, resin powder, sulfide and gas.

●The cleaning effect remains stable

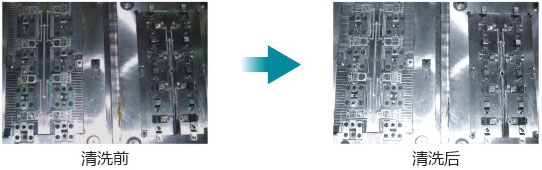

Cleaning effect

● Return the mold to the original brilliant color.

● Thoroughly remove any dirt from the mold surface.

● Even any complex shape of the mold can remove dirt.

● Has a good anti-rust function.

● Greatly reduce the product defect rate after mold cleaning.

● Compared with the traditional mold cleaning method, the cleaning time can be shortened to an alarming level, which makes the cleaning work easier, simple and efficient.

●The best combination of electrolysis and ultrasonic, the cleaning is made easy and simple with a special solution. And keep the cleaning effect lasting and stable.

Universal Scope

Gold, metal products, optics, machinery, locomotives, semiconductors, medical, communications, そののの

The role of electrolysis and ultrasound< /span>

●Using electrolysis, the object generates positive and negative molecules due to the action of electric current. Under the catalytic action of oxygen and hydrogen generated on the metal surface, the soiled part is rapidly decomposed, peeled off and floated out.

●Using the cavitation effect of ultrasonic waves, numerous small bubbles are generated to interact with the object. The blasting of the dirt on the workpiece is performed, and the dirt is automatically peeled off.

● The use of special solutions through a sufficient chemical effect to quickly decompose the dirt.

|

Intelligent automatic electrolytic mold cleaning machineFirst: save labor 90%; Second: reduce mold fouling rate 12%; Third: Extend the service life of the mold 10 years.

Intelligent automatic electrolytic mold cleaning machineFirst: save labor 90%; Second: reduce mold fouling rate 12%; Third: Extend the service life of the mold 10 years. Four-slot electrolytic mold cleaning machineFirst: save labor 50%; Second: reduce mold fouling rate 12%; Third: Extend the service life of the mold 10 years.

Four-slot electrolytic mold cleaning machineFirst: save labor 50%; Second: reduce mold fouling rate 12%; Third: Extend the service life of the mold 10 years. Waterway cleaning machineStable thermal conductivity shorten molding cycle Stable molding quality Increase productivity save energy consumption

Waterway cleaning machineStable thermal conductivity shorten molding cycle Stable molding quality Increase productivity save energy consumption Waterway cleaning machine (for 3D mold)Stable thermal conductivity shorten molding cycle Stable molding quality Increase productivity save energy consumption

Waterway cleaning machine (for 3D mold)Stable thermal conductivity shorten molding cycle Stable molding quality Increase productivity save energy consumption